Everything You Required to Learn About OEM Construction Parts

Wiki Article

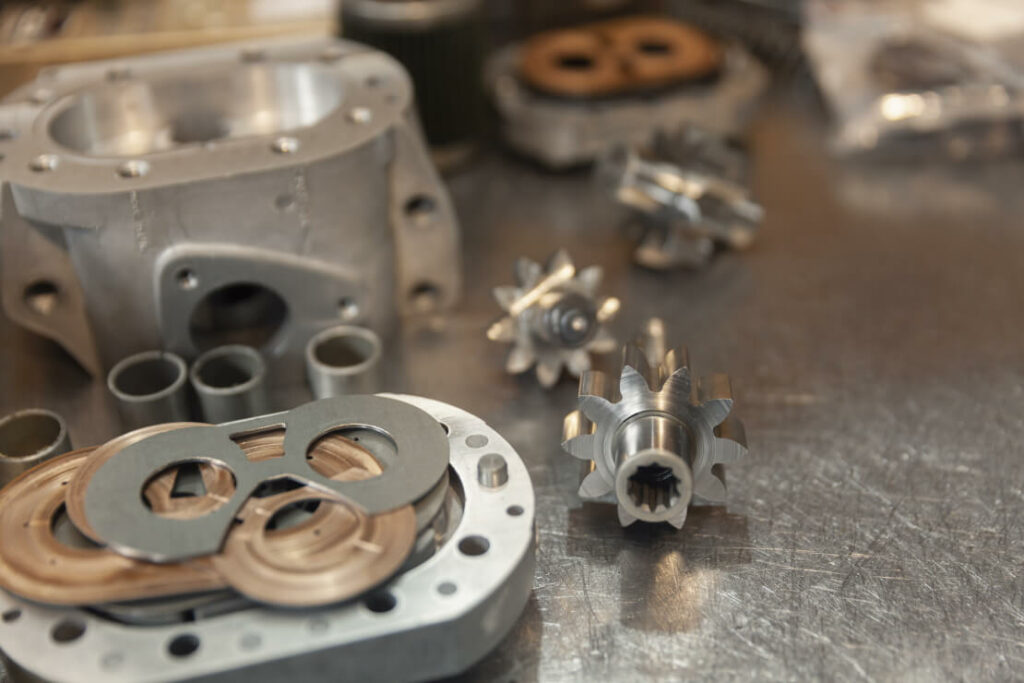

Exploring the Benefits of OEM Building Parts in Ensuring Seamless Operations at work Site

In the world of building procedures, the dependence on Original Devices Maker (OEM) construction parts plays a critical role in keeping the efficiency and functionality of heavy equipment and devices on job sites. These components are created to meet the specific specs and criteria set by the equipment makers, making sure optimum efficiency and compatibility. As the foundation of smooth procedures, the application of OEM construction components uses a variety of advantages that go beyond simple performance. From bolstering devices efficiency to improving safety measures and extending the lifespan of equipment, the benefits are manifold. It is crucial to discover in depth just how these OEM components add to smooth procedures and why they remain a cornerstone of success in the building sector.Improved Tools Efficiency

Boosted devices performance is an essential facet that underscores the significance of utilizing OEM construction components. Original Equipment Manufacturer (OEM) parts are specifically developed to fulfill the exact specs of the equipment, ensuring optimal performance and long life. When construction business make use of OEM components in their equipment, they can substantially enhance the efficiency and effectiveness of their tools on duty site.One trick advantage of OEM building parts is their compatibility with the equipment they are meant for. OEM components are engineered to seamlessly incorporate with the equipment, lowering the danger of malfunctions or break downs that can occur with aftermarket or common components (Oem Construction Parts). This compatibility equates into enhanced equipment performance, as OEM components maintain the designated capability and top quality of the equipment

Moreover, OEM building and construction parts undertake rigorous testing and quality control procedures to fulfill sector standards. This attention to information makes sure that the components are durable, dependable, and efficient in withstanding the demanding conditions of building and construction job. By utilizing OEM building parts, business can optimize the efficiency of their tools, leading to enhanced efficiency and price financial savings over time.

Decreased Downtime

By utilizing OEM building and construction components, construction business can dramatically minimize downtime, thus boosting total operational effectiveness. Downtime on a building website can be pricey, triggering hold-ups in task timelines and enhancing labor expenses. OEM construction parts are made to fit seamlessly with the original equipment, guaranteeing optimum performance and reducing the danger of failures.

When making use of OEM components, building companies can lessen the time required for upkeep and fixings. OEM parts are constructed to precise requirements, guaranteeing an ideal fit and dependable performance. This reduces the opportunities of unanticipated tools failures that can cause unintended downtime.

Furthermore, OEM components are known for their top quality and resilience, giving longer-lasting options compared to aftermarket alternatives. By investing in OEM building components, firms can avoid constant replacements and fixings, ultimately saving time and money in the future.

Improved Safety And Security Procedures

Executing OEM building and construction parts can bring about a considerable improvement in security actions on construction sites. OEM components are especially created to fit and function properly within the equipment they are meant for, making sure optimal efficiency and minimizing the threat of malfunctions that could compromise security. By utilizing OEM parts, building firms can preserve the integrity of their tools, minimizing the possibilities of failings or crashes as a result of inappropriate or malfunctioning elements.Additionally, OEM parts undergo rigorous screening and quality assurance actions to satisfy industry criteria and specs. This commitment to high quality and dependability equates directly right into improved safety on the work website. Employees can believe in the equipment they are making use of, knowing that it is furnished with real OEM parts that have actually been confirmed to carry out securely and efficiently.

In enhancement to lowering the possibility of equipment-related crashes, OEM components also contribute to a more secure workplace by advertising correct performance of machinery and adherence to safety procedures. In general, buying OEM building parts is an aggressive action towards boosting safety steps and guaranteeing the well-being of workers in the construction sector.

Extended Equipment Life Expectancy

Utilizing OEM construction components can significantly prolong the functional life-span of tools on building websites. Original Tools Maker (OEM) parts are crafted to exact specifications, ensuring compatibility and ideal performance within the devices they are created for. By utilizing OEM building and construction components, building and construction business can preserve the integrity and capability of their equipment, bring about prolonged devices life expectancy.One trick benefit of OEM building and construction components is their top quality and dependability. These components are manufactured to fulfill the same requirements as the initial parts, ensuring a correct fit and performance. This accuracy in style and building and construction minimizes the danger of premature damage on the devices, eventually boosting its durability.

Furthermore, OEM parts frequently come with service warranties, giving included guarantee to construction firms relating to the longevity and performance of the components. This guarantee insurance coverage can provide comfort and financial protection in situation of any kind of unexpected issues, even more sustaining the extended lifespan of the devices. By investing in OEM construction parts, construction companies can make certain that their equipment runs efficiently for an extended duration, making best use of efficiency and minimizing downtime.

Streamlined Maintenance Processes

Having developed the advantages of OEM construction parts in lengthening the functional life expectancy of equipment, a concentrate on structured maintenance processes becomes extremely important for ensuring ongoing efficiency pop over to this site and integrity on building sites. Streamlined upkeep procedures refer to the organized method taken to maintenance machinery and equipment with precision and timeliness. By adhering to a well-structured upkeep view timetable that consists of normal evaluations, cleaning, lubrication, and small repair services using OEM parts, construction firms can minimize downtime and avoid pricey break downs.Executing a proactive maintenance approach not only enhances the general efficiency of the equipment however also contributes to a safer working setting for building employees. Inevitably, prioritizing streamlined maintenance procedures with OEM building and construction components is vital for optimizing performance and making sure smooth procedures on the work site.

Conclusion

In the world of building procedures, the reliance on Original Tools Maker (OEM) building and construction components plays a pivotal duty in keeping the performance and functionality of hefty machinery and equipment on work websites.Applying OEM building and construction components can lead to visit a significant enhancement in safety measures on building and construction sites.Making use of OEM building and construction components can dramatically extend the operational life expectancy of devices on building and construction websites. By using OEM building and construction components, building business can keep the honesty and performance of their machinery, leading to extensive devices life expectancy.

Having actually developed the advantages of OEM building and construction parts in prolonging the operational life expectancy of devices, a focus on streamlined upkeep procedures becomes vital for guaranteeing continued performance and dependability on construction websites.

Report this wiki page